Clean energy from wastewater

The largest sewer-heat recovery system in North America

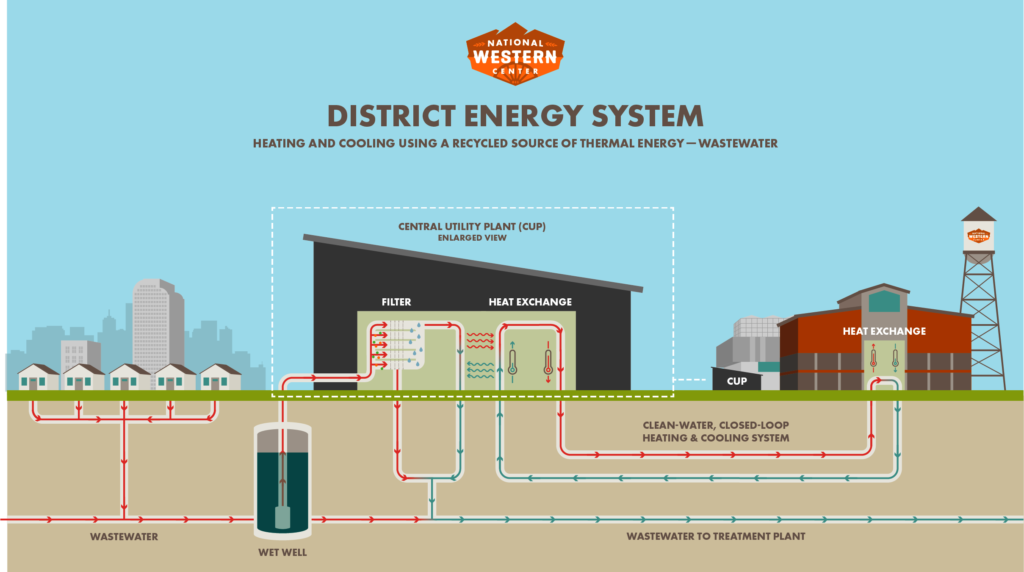

In an innovative approach to an operational necessity, the campus will source nearly 90 percent of its heating and cooling from a recycled source of thermal energy — a sewer pipeline that runs through the site — rather than burning fossil fuels. It’s all part of our commitment to sustainability.

How it Works

Sewer-heat recovery

The planned system uses both sewer-heat recovery and a district energy approach. Sewer heat recovery systems pull thermal energy from wastewater instead of burning natural gas. Using this system, the 250-acre campus will avoid emitting an estimated 2,600 metric tons of carbon (CO2) per year.

Used water that goes down the drains of our showers, sinks, tubs, dishwashers, washing machines and toilets maintains a fairly constant temperature as it travels through the sewer pipe. In a sewer heat recovery system, a heat pump is used to capture the warmth of wastewater and transfer it to a clean water distribution pipe that enters individual buildings. It is a closed-loop system, meaning the wastewater never touches the clean water. The wastewater flows back into the sewer; the heat is transferred to the clean water that is distributed to heat and cool the buildings.

Learn more via NPR Morning Edition.

A wastewater pipeline blocked access to the South Platte River for decades. Crews have removed it, and built a new pipeline underground. The sewer-heat recovery system will harness the new pipeline’s thermal energy to heat and cool campus buildings.

District energy

District energy systems pump warm water via a closed-loop network of pipes from a central plant to a group of buildings, instead of each building having its own heating and cooling system. The results are high efficiency, lower capital costs, and a reliable and resilient energy source during outages.

Based on its low-profile design, the district energy system will have virtually no external impact on surrounding uses.

Benefits of the System

Low-carbon and sustainable.

Using a local source of recycled energy instead of emitting CO2 by burning fossil fuels is the emissions equivalent of eliminating 6.6 million passenger vehicle passenger miles every year. The impact is local and global.

Healthier for our communities.

Reducing fossil fuel use means reducing air pollution and associated health impacts. To build the system, crews will bury the sewer pipeline that runs alongside the river, alleviating its odors and opening up recreational space for all to enjoy.

Reliable and resilient.

Buildings will have efficient heating and cooling, even if natural gas is not available — opening the door for the campus to be a place of refuge during extreme weather events or outages.

Price-certain and cost-effective.

Buildings everywhere have heating and cooling costs no matter the energy system. The cost for this innovative, custom approach is comparable to traditional systems over the long run, and not subject to price fluctuations of natural gas.

Partners

The system will be built and operated by EAS Energy Partners (EAS), through an agreement with the National Western Center. EAS is comprised of CenTrio Energy, the largest core-competency district energy operator in North America, AECOM Technical Services Inc. and Denver-based Saunders Construction.

Partners in the district energy system and its future users include the City and County of Denver, CSU Spur and the National Western Stock Show. Metro Water Recovery (formerly the Metro Wastewater Reclamation District) is providing thermal energy at no cost and has made possible the burying of its sewer pipeline that runs through the National Western Center site.

How it all Began

The 2015 National Western Center Master Plan set ambitious sustainability goals for the campus, including a principle to “embrace an ethic of regeneration” for the site itself.

As the campus redevelopment plan came together, the city of Denver project team approached Metro Water Recovery about the possibility of relocating its 7-foot-tall, aboveground pipeline that ran through the site, to allow access to the river from the campus.

At the time, Metro Water Recovery was working on regulating the temperature of the clean wastewater (“effluent”) it returns to the South Platte River. Recognizing the potential environmental benefits of using thermal energy from the pipeline to heat and cool buildings, including cooling of the effluent, Metro Water Recovery conducted studies to explore the possibility. Their study prompted further studies by the City and County of Denver, Metro Water Recovery and Xcel Energy. The results confirmed this approach was technically feasible. Faculty and students at Colorado State University – a leader in sustainability, and the first institution in the world to achieve STARS Platinum ranking – also studied the system design.

City officials worked to identify a campus energy partner with the right expertise. In 2018 EAS was selected from among seven proposers in a competitive procurement, and the National Western Center signed a long-term energy agreement with EAS in 2020.

Education and Employment Opportunities

During design and construction, the system will bring new employment opportunities, including specifically for minority and women-owned businesses. EAS Energy Partners will also incorporate educational tours for school groups. The CSU Spur campus, when opened in 2022, will host ongoing research and student learning, in collaboration with EAS.

FAQs

How reliable is district energy?

Most district energy systems operate at four nines of reliability, meaning service is available 99.99 percent of the time on an annual basis. Operational reliability has been a hallmark of the district energy industry.

How does the system benefit the river?

Using waste heat offers a co-benefit for wastewater management in Denver. In the winter, when Metro Water Recovery returns clean effluent to the river, it’s better for that effluent to be at a lower temperature — closer to the river’s temperature — so that fish and other aquatic life are not exposed to significant temperature changes. The district energy system delivers lower-temperature wastewater to Metro Water Recovery’s treatment facility than the pipeline alone did.

Will odors be a problem?

No. The district energy system is a closed piping system that circulates clean water (not wastewater) through the campus; there is no odor associated with the distribution piping. The handling of wastewater within the central utility plant will also be within a closed system. The connection to the sewer occurs in a wet well linked to an existing manhole; a biofilter adjacent to the CUP will alleviate any odor problems associated with the wastewater pipe and the connection to the pipe.

Does the system have the capacity to expand?

Yes, the system could be expanded to heat and cool buildings in future phases of the National Western Center project. Expanding the system would likely increase energy- and cost-efficiencies for all buildings and users, and avoid even more greenhouse gas emissions.

How does the cost compare to traditional energy approaches?

This system is being delivered at a cost comparable to traditional natural gas systems from a total cost of ownership perspective over its lifetime. On-campus building owners will pay for the system through event fees and monthly energy bills. A small premium for this system over 40 years over a traditional system is acceptable to campus partners because:

- This system is four times more efficient than traditional heating and cooling systems, and it helps the campus make progress toward its energy goals.

- The potential to expand the system as the campus grows could mean more cost efficiencies for all users.

- The use of recycled energy — in a system adaptable to future clean-energy technologies — stabilizes energy costs for building owners and customers, compared to fossil fuels with prices that are more volatile or potentially subject to future carbon taxes.

- The environmental value, reliability and resiliency of the system, and quality of the provider are worth the modest premium.

- To help make the project more cost effective, the City and County of Denver Department of Public Health and Environment provided a $1 million grant toward the project from its enterprise fund that supports environmental projects.